INNOVATION

Robotics

Innovation in Robotics

At Treske, our mission is Innovation. Our culture of continuous improvement means that in every aspect of our work, we seek to push the boundaries of what’s possible.

This extends to our partnerships. We are eager to align with companies who not only share this commitment to innovation, but empower it. We’re excited to announce two new revolutionary pieces of equipment being added to our production floor.

Robotic Inspection

If you’re familiar with Treske, you know we’re fanatical about consistently delivering high quality parts. That wouldn’t be possible without a robust inspection process for every product that goes out the door.

We’ve now added to our inspection capabilities with Hexagon TEMPO – which enables completely autonomous measurements. This automated part loading system will not only increase our throughput and maximize our operational capacity, it’ll free up our team to focus their attention on other important tasks.

Some highlights:

- 100% lights out

- Eliminates load errors

- Quick set up / change over

Robotic Loading

Likewise, one of our core values is Push It Forward, which is why our team is constantly looking for ways to make our processes smarter, faster, and more efficient. One way of doing this is to streamline time-consuming tasks like loading and unloading machine cells.

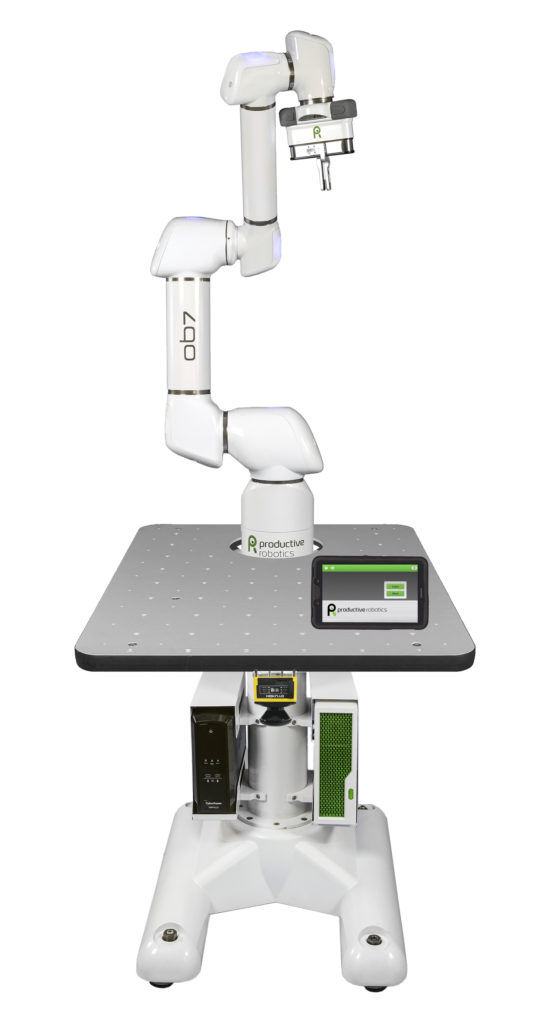

That’s where OB7 comes in. OB7 is a 7-axis collaborative robot (or “cobot”) for automating CNC machine tending. Designed and manufactured in the USA, OB7 is uniquely designed from the ground up and allows for our team to automate some of their own production tasks.

- 100% lights out

- Eliminate load errors

- Maximum efficiency

Having the equipment is one thing, leveraging it to its full potential is another. Learn how Treske continues to optimize machining technology on our Facility Page.