FACILITY

Optimized Machining Technology

Streamlined Operations

Our state-of-the-art facility and equipment gives us the repeatability, consistency, and quality customers have come to expect. These resources, combined with our continuous improvement methodology, mean that every machine in our facility is running at maximum efficiency and adding maximum value to our customers.

Facility

50

CNC MACHINES

190

EMPLOYEES

120,000

SQ. FT | 2 BUILDINGS

We continue to make investments in our facility, equipment, technology, and training to ensure ongoing value for our customers.

Equipment

Part Mix

At Treske, we offer a wide range of machining capabilities. From low, medium, and high volume production to complex geometry, we offer solutions to meet your manufacturing needs.

HIGH VOLUME /

LOW MIX

- Automated cells allow efficient production and scalability of high volume projects

- Scalability allows for production spikes with quick response times

- Cell technology enables competitive costing through 24/7 machine utilization

LOW VOLUME /

HIGH MIX

- Resident set-up allows rapid changeover between multiple jobs

- Improved run to run repeatability

- Dynamic scheduling enables efficiencies in short runs

COMPLEX

GEOMETRY

- Experienced team of CNC programmers, engineers, and set-up machinists

- Collaboration to develop efficient and repeatable manufacturing processes

- Automation and up-to-date equipment allow for part to part repeatability

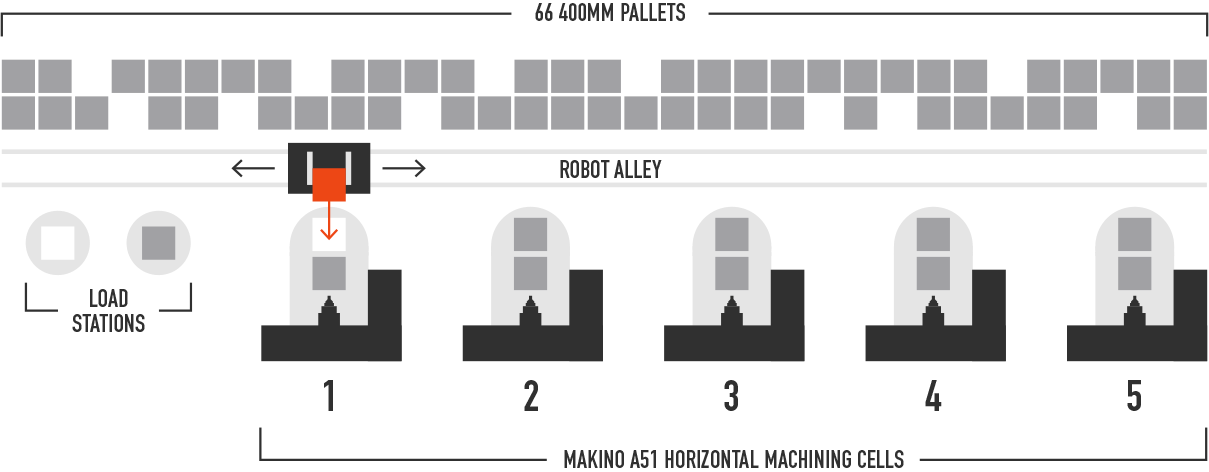

Automated Manufacturing

21

MACHINES

9

CELLS

195

PALLETS

11

ROBOTS

At the heart of our cellular manufacturing are nine automated horizontal machining cells consisting of:

- 10 Makino A51s (4 axis)

- 9 Makino A61s (4 axis)

- 1 Makino D500 (5 axis)

- 1 Mori Seiki NHX5000 (4 axis)

Each is equipped with our proprietary manufacturing control system, including dynamic scheduling and real-time inspection reporting.

Additional Capabilities

ASSEMBLY

Contract assembly for everything from hardware installations to full mechanical assemblies.

LASER

Laser engrave capabilities for serializations or general nomenclature.

ENGINEERING

Engineering support offering DFM (design for manufacture) recommendations, CATIA, Solidworks, and CAD/CAM capabilities.

MICRO DEBURR

Microscopes, vision systems, specialty tools, and training for FOD detection and burr removal on deep cross sections, blind holes, or tight tolerance features requiring specialized attention.